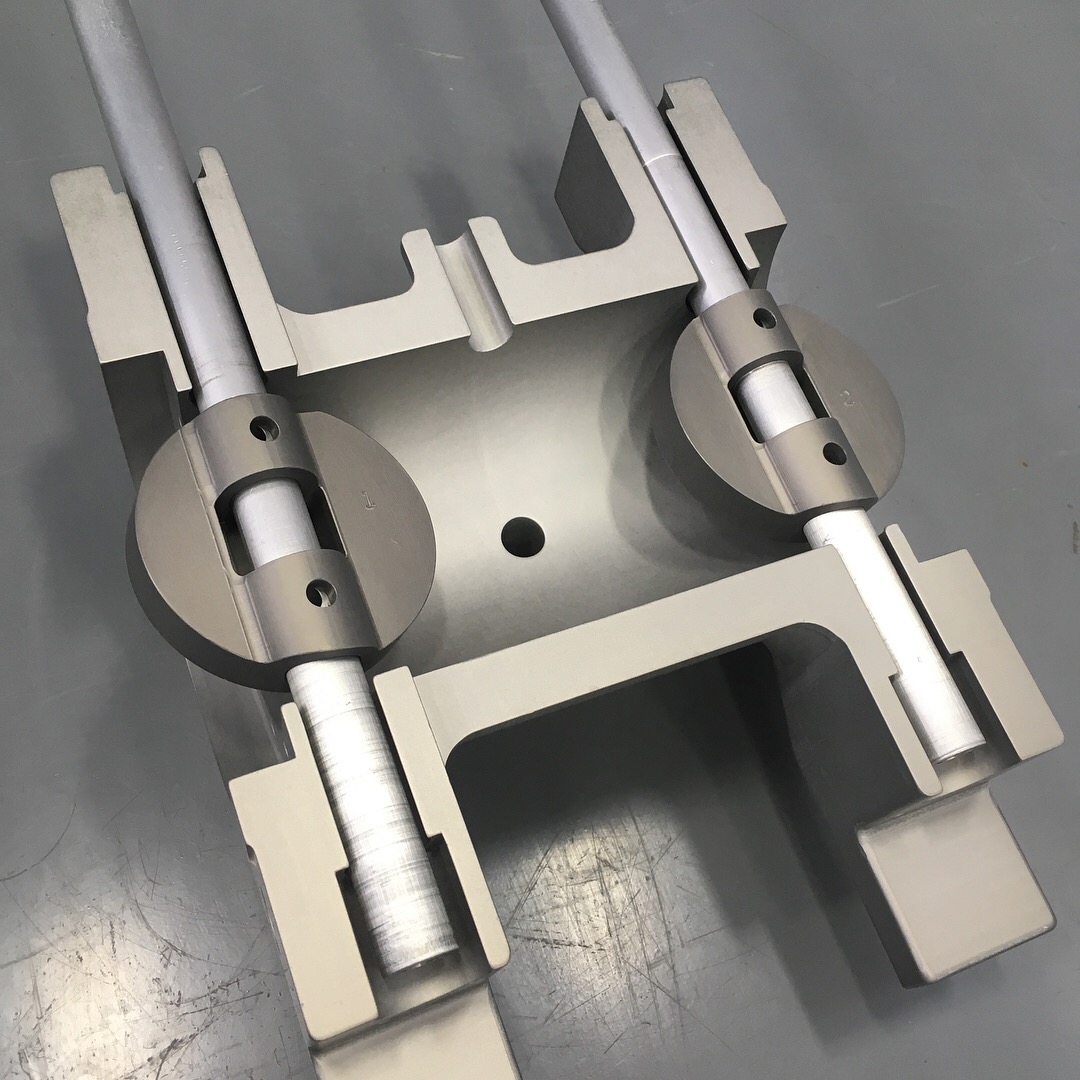

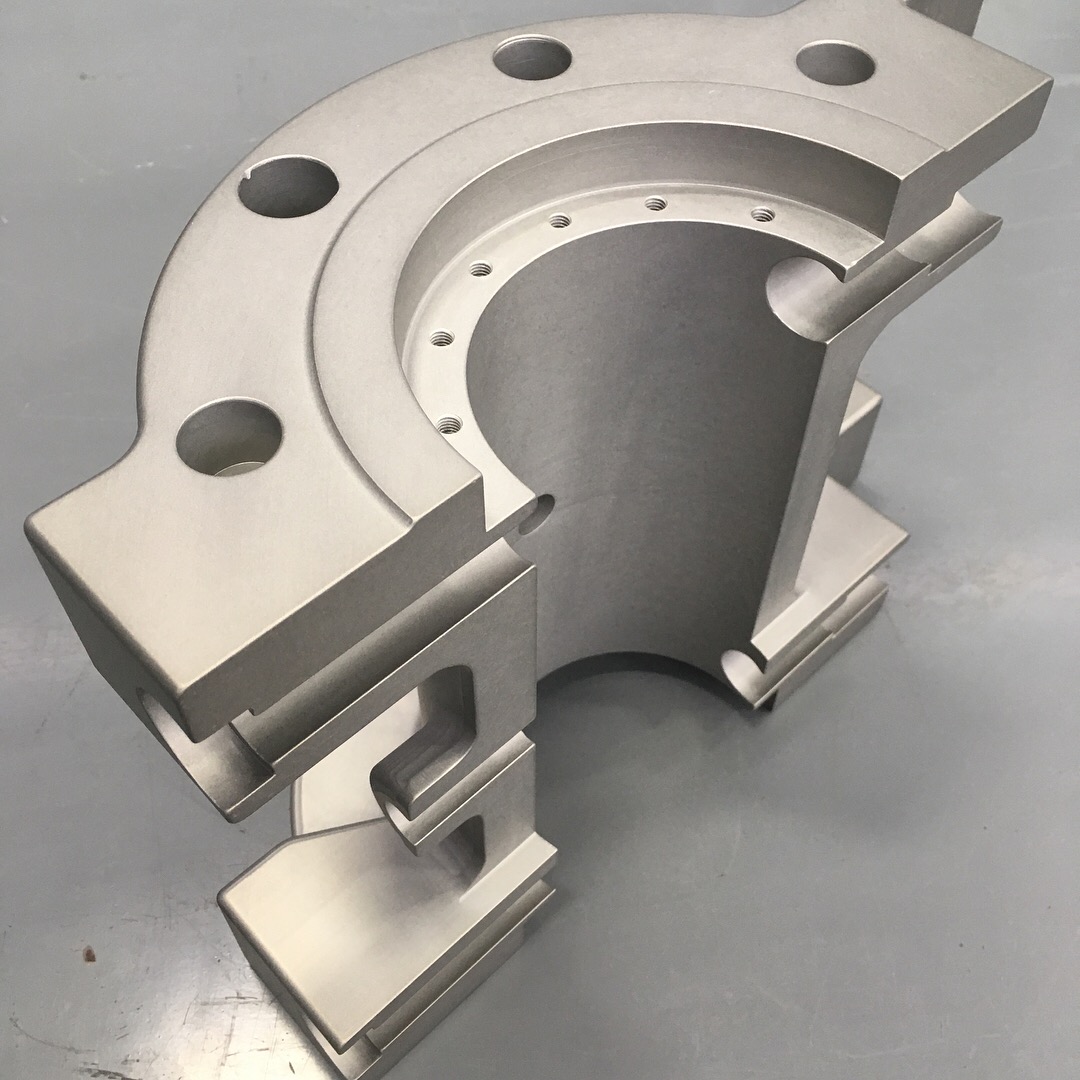

Anodizing - Type III Hardcoat

Houston Anodizing offers aluminum hardcoat anodizing (Type III) for dyed and non-dyed parts at our state-of-the-art facility in Houston, Texas. Hardcoat aluminum anodizing provides a surface that is more wear resistant and has a smoother and harder finish than standard anodizing. Please note that not all colors are well suited for use with a Type III anodic layer due to the smaller coating pore size and darker color (typically gray-black or gray-bronze).

The typical thickness produced by engineered anodizing MIL-A-8625 (Type III) is 0.0005”- 0.002”, but the coating thickness can be controlled with exceptional accuracy. The coating created by Type III anodizing penetrates 50% of the surface, with the remaining 50% of the coating building up on the surface. Since hard anodizing alters surface thickness, it’s important to note that the process will affect the final dimensions of parts with tight tolerances.

After an aluminum part has been hardcoat anodized, there is an option to have it sealed. If the main function of the application is to obtain the maximum degree of abrasion or wear resistance, the coating should not be sealed. If the main function of the application is for corrosion resistance, and reduced abrasion resistance is not an issue, sealing is advised.

Contact us today or request a quote for anodized aluminum parts.

Standard Specifications

MIL-A-8625 Type III (Class 1 & 2)

AMS 2471

RoHS, REACH, ELV & WEEE Compliant

Performance Benefits

Superior Wear Resistance

Excellent Corrosion Resistance

Heat Dissipation

Dielectric Properties (Electrical Insulation)

Bonding

Receptive Metals

Aluminum Alloy

Thickness

.0005-.003”